PROUDLY MADE IN AUSTRALIA —

Our Facilities

-

Vertically Integrated Manufacturing

-

As one of Australia’s few remaining textile manufacturers, Silver Fleece continues to grow as a vertically integrated producer of both textiles and garments, meaning we manage multiple stages of the supply chain. From design and weaving high-quality fabrics to crafting finished garments and distribution, we can manage every step of the process in-house to ensure exceptional quality, sustainability and care in everything we do.

— DESIGN

— INNOVATION

— KNITTING

— DYEING

— FINISHING

— CUT, MAKE & TRIM

— DISTRIBUTION

Innovation

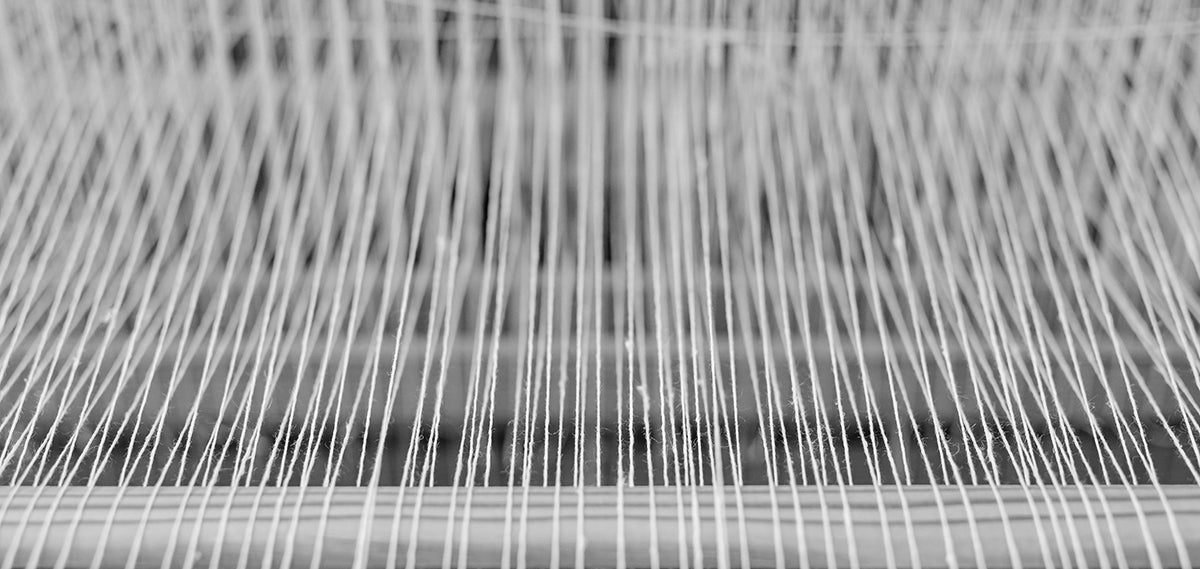

Image: Threads on single hand-knitting machine.

With a legacy built on craftsmanship and innovation, Silver Fleece has evolved from a single hand-knitting machine in 1951 to pioneering 3D-knitted textiles in 2025. Driven by research and development and a commitment to sustainability, we offer highly customised garment solutions for businesses of all sizes, supported by in-house textile testing and development capabilities.

Knitting

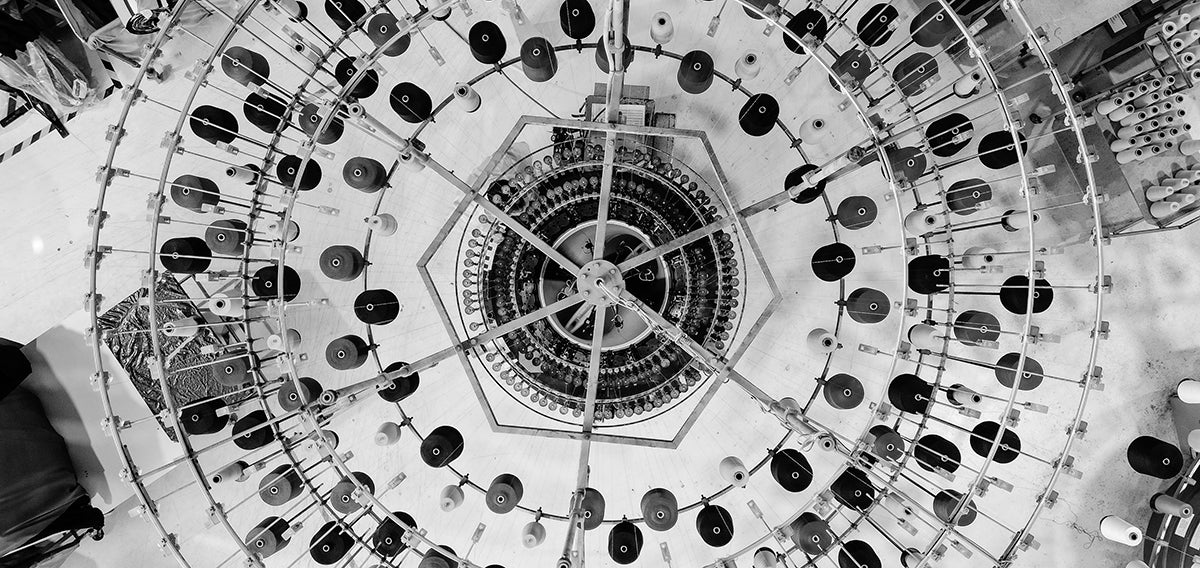

Image: 3D Circular Knitting Machine.

Backed by decades of expertise and a diverse fleet of circular knitting machines, Silver Fleece can craft nearly any fibre into a wide range of configurations—from classic knits to intricate jacquards.

Dyeing

Image: Inside dye house.

Silver Fleece partners with trusted Australian dyeing suppliers who use advanced jet dyeing technology. These machines offer high efficiency with a lower environmental impact—requiring less water, chemicals, and energy than conventional methods, while still delivering vibrant, high-quality finishes for our garments.

Finishing

Image: Temperature controls on finishing machine.

Fabric finishing is a key part of our process at Silver Fleece—enhancing textile performance, appearance, and feel to meet the specific needs of every client.

Our in-house stenter machine applies modern finishing techniques that transform our fabrics into high-performing, durable garments. This process sets the colour fastness and preshrinking of the fabric making our manufacturing process the highest quality.

Whether it's improving comfort, function, or aesthetics, our commitment is to deliver quality finishes in a way that aligns with our focus on sustainability and innovation.

Cut, Make & Trim

Image: The sewing room.

We bring your designs to life in 3 streamlined steps:

1. Sampling

See your vision take shape with a prototype that brings your design to life. This stage helps refine fit, fabric, and pattern details before full production.

2. Grading

Once the sample is approved, we scale your pattern to all required sizes—ensuring consistency in shape, fit, and proportion across the range.

3. Production

With patterns finalised, we begin cutting, making, and finishing your garments using premium materials and machinery—delivering quality from start to finish.

Gold Standard in Sustainability

From ethically sourced Australian wool to low-impact production and long-lasting garments, we’re knitting a more responsible future—helping our customers reduce their footprint without compromising on quality or craft.